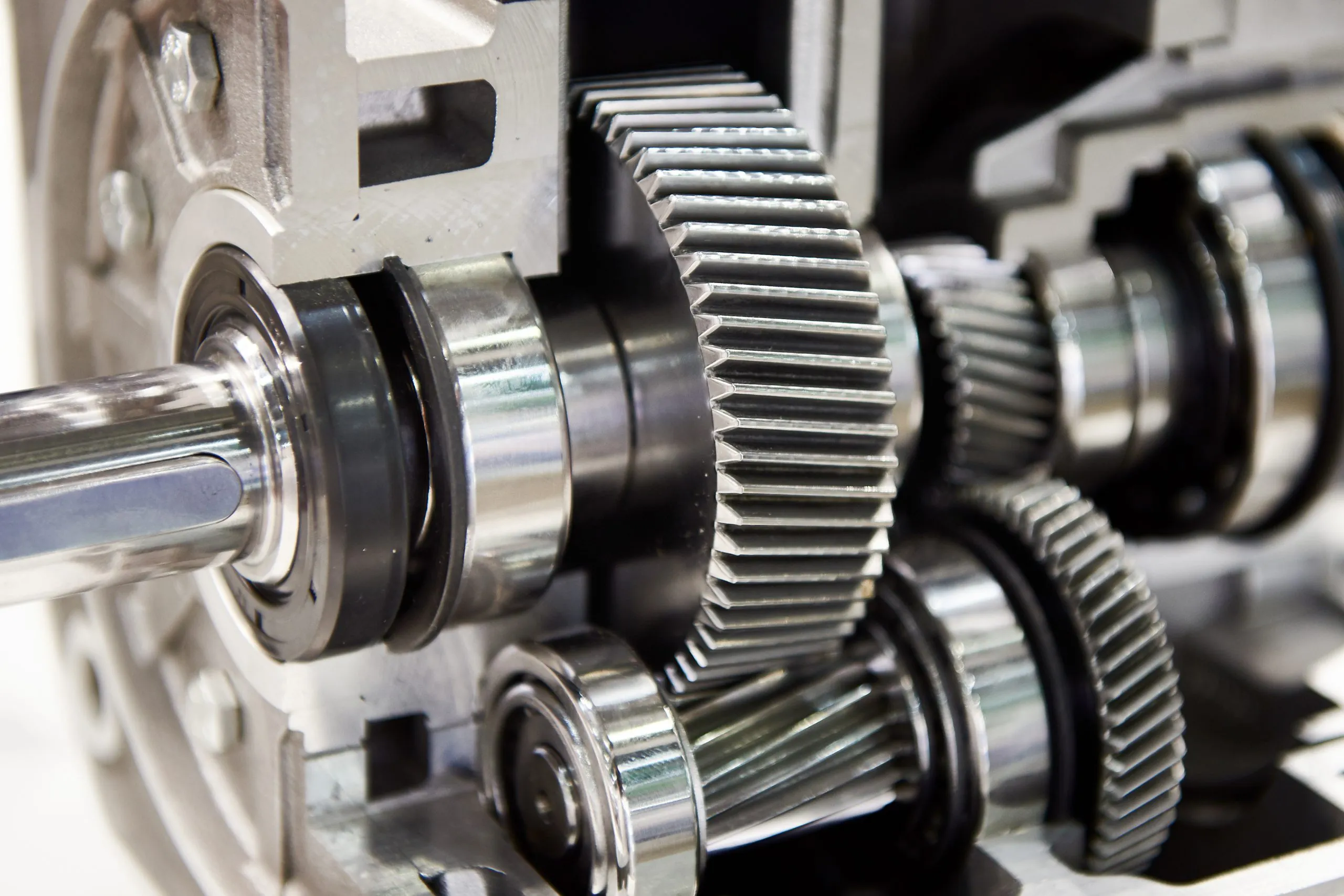

HELICAL GEARBOX

Manufacturer & Supplier

Helical gearbox is a mechanical transmission system that uses helical gears to transfer power between two rotating shafts. They are commonly used in industrial applications that require high torque and efficiency.

About

Helical Gearbox Design

A helical gear box is designed with a helical gear whose teeth are at an Angle to the rotating shaft. This Angle is usually between 15 and 45 degrees, allowing for smooth, quiet operation. Helical gears also have a larger contact area than spur gears, resulting in a higher torque capacity.

1350

Products

1486

Customers

17

Years

work

How Does Helical Gearbox Work?

A helical gearbox works by transferring power between two rotating shafts through a pair of helical gears. The gear teeth in a helical gearbox are at an Angle to the rotating shaft, usually between 15 and 45 degrees. This design allows gear teeth to gradually mesh with each other, resulting in smoother, quieter operation compared to other types of gears.

When the input shaft of the helical gear box turns, it also causes the helical gear to turn. The angled teeth of the gears make them gradually touch each other, thus reducing impact and noise. As the gears turn, they transfer power from the input shaft to the output shaft.

Advantages Of Helical Gearbox:

-

Higher torque capacity: The helical gears in a helical gearbox have a greater contact area compared to spur gears, which allows them to transmit higher torque loads.

-

Smooth and quiet operation: The angled teeth of the helical gears allow them to gradually engage with each other, resulting in a smoother and quieter operation compared to spur gears.

-

Higher efficiency: Helical gears in helical gears are more efficient than other types of gears, resulting in reduced power losses and improved energy efficiency.

-

Higher Carrying capacity: Helical gearboxes have higher carrying capacity compared to other types of gearboxes, which makes them suitable for heavy industrial applications.

-

Longer lifespan: The smooth and gradual engagement of the helical gears results in less wear and tear, which extends the lifespan of the gearbox.

types

Types Of Helical Gearbox

Planetary Helical Gearbox

This type of gear box has a central sun gear meshing with multiple planetary gears, which in turn meshes with a ring gear to transfer power between the input and output shafts. They are typically used in high-precision applications requiring compact design and high torque capacity, such as robotics and aerospace applications.

Bevel Helical Gearbox

This type of transmission has angled teeth in the gears that transfer power between the input and output shafts. They are usually used in applications requiring high torque and limited space.

Worm Helical Gearbox

This type of gear box has a worm gear that engages with a helical gear to transfer power between the input and output shafts. They are commonly used in low-speed applications requiring high torques, such as heavy industrial machinery.

China Custom CZPT Drive Speed Electric Motor Gearbox Helical Gear Parallel Shaft Gearboxes bevel gearbox

Product Description Aokman Drive speed electric motor gearbox helical gear Parallel Shaft Gearboxes Components: 1. Housing: Cast Iron 2. Gears: Hardened Helical Gears 3. Input Configurations: Equipped with Electric Motors CZPT Shaft Input IEC-normalized Motor Flange...

China wholesaler Bevel Helical Gearbox K Series automatic gearbox

China Professional Manufacturer R Series Helical Gear Box with Motor Cast Iron Manual Transmission Helical Gearbox Reduction Gears with Great quality

Products

Helical Gearbox For Sale

If you want to buy helical gearbox, we are your best choice, we also provide other types of helical gearbox, if you need please contact us.

Conveyor Systems

Mining Equipment

Power Ggeneration

Marine Applications

Industrial Machinery

Automotive Applications

Helical Gearbox Application

Why Choose Us?

We are one of the best helical gearbox suppliers.We can offer wide helical gearbox stock.We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service.We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information and cooperate with us!