Product Description

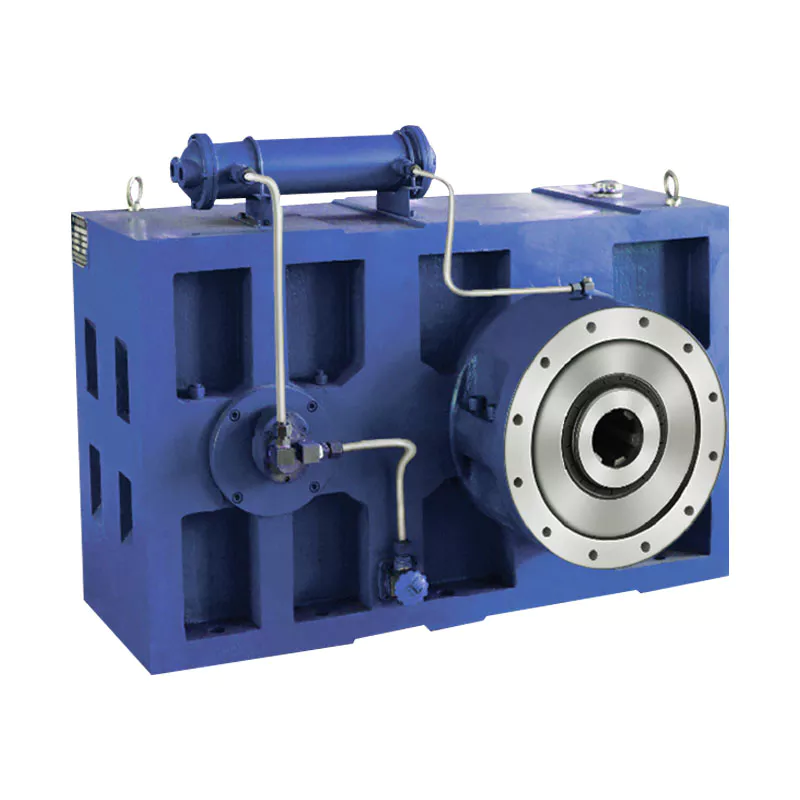

R series motor speed reducer helical gearbox electric reverse gear box for buggy industry in line shaft Coaxial geared motors auto part reducer transmission

R helical concentric gearbox speed reducer decelerator has the features of high versatility,good combination and heavy loading capability, along with other merits such as easy to attain various transmission ratios, high efficiency, low vibrationand high permissible axis radial load. This series can not only be combined with various kinds of reducers and variators and meet the requirements, but also beadvantage of localization of related transmission equipment.

1) Output speed: 0.6~1,571rpm

2) Output torque: up to 18,000N.m

3) Motor power: 0.18~160kW

4) Mounted form: foot-mounted and flange-mounted mounting

| Product Name | SLR Series Rigid Tooth helical reducer |

| Gear Material | 20CrMnTi |

| Case Material | HT250 |

| Shaft Material | 20CrMnTi |

| Gear Processing | Grinding finish by HOFLER Grinding Machines |

| Color | Customized |

| Noise Test | Bellow 65dB |

company information

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | – |

| Gear Shape: | – |

| Step: | – |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

Types of Helical Gear Arrangements

Yes, there are different types of helical gear arrangements available to suit various applications and requirements. Some of the common helical gear arrangements include:

Parallel Shaft Arrangement: In this arrangement, the axes of the driving and driven shafts are parallel to each other. It is the most straightforward configuration and is often used in applications where space is not a constraint, and the gearboxes can be placed side by side.

Right-Angle Shaft Arrangement: In a right-angle arrangement, the driving and driven shafts are positioned at a 90-degree angle to each other. This arrangement is space-saving and is commonly used in applications where the layout requires a change in direction of the power transmission.

Double Helical Gear Arrangement (Herringbone Gears): Double helical gears consist of two sets of helical teeth facing each other. This arrangement helps to cancel out axial forces and reduces the net thrust load on bearings. It is often used in heavy-duty applications to minimize wear and vibration.

Crossed Helical Gear Arrangement (Screw Gears): In this configuration, the axes of the driving and driven shafts are neither parallel nor intersecting. It is suitable for applications requiring non-parallel and non-intersecting shafts.

The choice of helical gear arrangement depends on factors such as available space, power transmission requirements, and the desired layout of the machinery or equipment. Each arrangement has its advantages and disadvantages, and selecting the appropriate one is crucial for achieving optimal performance and efficiency.

Safety Precautions for Operating Machinery with Helical Gear Systems

When operating machinery equipped with helical gear systems, it’s crucial to prioritize safety to prevent accidents and ensure the well-being of operators and equipment. Here are the key safety precautions to consider:

- Training and Familiarity: Operators should receive proper training on the equipment’s operation, including the helical gear system. They should be familiar with the controls, emergency procedures, and potential hazards.

- Protective Gear: Operators should wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, helmets, and ear protection, depending on the application’s requirements.

- Lockout/Tagout: Before performing maintenance or repairs, follow lockout/tagout procedures to isolate the machinery from its power source and prevent accidental startup.

- Regular Inspections: Conduct routine inspections of the helical gear system and other machinery components to identify signs of wear, damage, or malfunction. Address any issues promptly to avoid unsafe conditions.

- Proper Lubrication: Ensure the helical gear system is adequately lubricated according to manufacturer recommendations. Proper lubrication reduces friction, wear, and heat buildup, enhancing both performance and safety.

- Emergency Stop: Machinery should be equipped with clearly marked emergency stop buttons or switches that operators can use to halt operations immediately in case of an emergency.

- Cleaning and Housekeeping: Maintain a clean work environment by removing debris, oil spills, and other potential hazards. Good housekeeping minimizes slip and trip hazards and promotes safe operation.

- Load Capacity: Adhere to the recommended load capacities specified by the manufacturer for both the helical gear system and the machinery as a whole. Overloading can lead to accelerated wear and potential failures.

- Avoid Loose Clothing: Operators should avoid wearing loose clothing, jewelry, or other items that could become entangled in the machinery, leading to accidents.

- Safe Working Distances: Establish safe working distances from moving parts of the machinery, including the helical gear system, to prevent accidental contact and ensure operator safety.

- Regular Maintenance: Follow the manufacturer’s maintenance schedule and guidelines for the helical gear system. Regular maintenance reduces the risk of unexpected failures and promotes safe and reliable operation.

Prioritizing safety when operating machinery with helical gear systems is essential to prevent accidents, protect operators, and maintain efficient operations. Following these precautions and promoting a safety-conscious culture can significantly contribute to a safe working environment.

Noise and Vibration Levels in Helical Gearboxes

Helical gearboxes are known for their relatively low noise and vibration levels compared to some other types of gears. However, there are still certain factors that can influence the noise and vibration levels in helical gear systems:

- Helix Angle: The helix angle of helical gears helps to distribute the load over multiple teeth, reducing impact forces and resulting in smoother meshing. This contributes to lower noise and vibration levels.

- Precision Manufacturing: High-precision manufacturing processes can ensure better gear tooth geometry and minimize irregularities that could lead to noise and vibration.

- Lubrication: Proper lubrication is crucial for reducing friction and damping vibrations between gear teeth. Insufficient or improper lubrication can lead to increased noise levels.

- Alignment: Proper alignment of gears is essential to minimize misalignment-induced noise and vibration. Misalignment can cause uneven tooth contact and lead to increased noise and vibration.

- Load Distribution: Helical gears distribute loads over multiple teeth, which helps in reducing localized stresses and vibrations that could cause noise.

- Material Quality: High-quality materials with good damping properties can help absorb vibrations and reduce noise transmission.

- Operating Conditions: Factors such as operating speed, load, temperature, and gear backlash can influence noise and vibration levels.

Overall, helical gearboxes are designed to provide smoother and quieter operation compared to other gear types. However, the noise and vibration levels can still vary based on design, manufacturing quality, and operational factors. Engineers can optimize gear design and operating conditions to achieve the desired noise and vibration characteristics for specific applications.

editor by CX 2023-09-11