Product Description

|

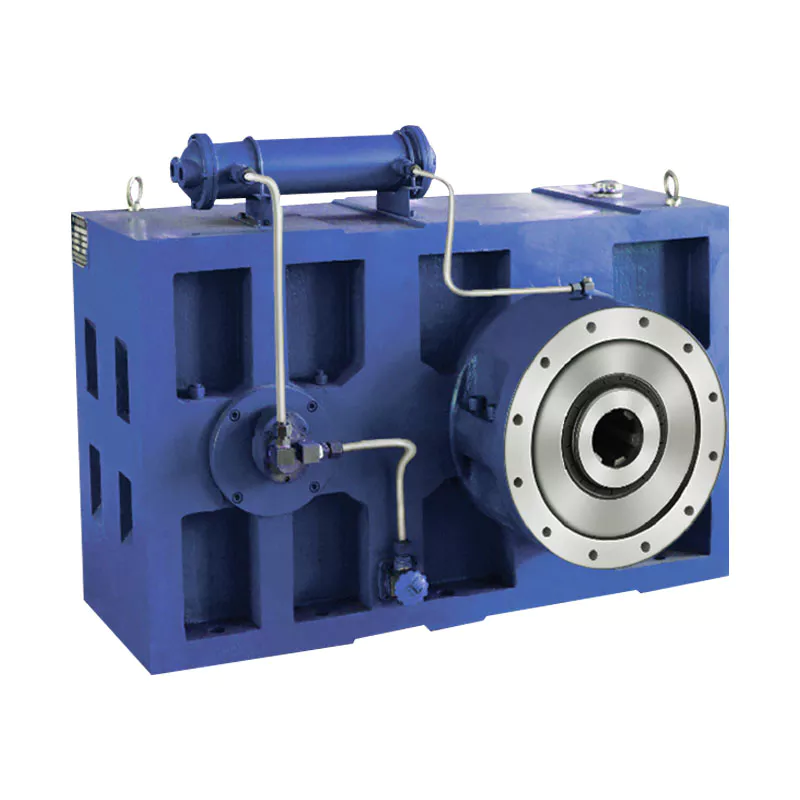

K series helical bevel speed gearbox reducer |

|

|

Product name |

Model K 107 series helical bevel gearbox motor reducer with oil seal overload parallel transmission 90 degree China factory |

|

Warranty |

1 year |

|

Applicable Industries |

Hotels, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Home Use, Retail, |

|

Weight (KG) |

50KG |

|

Customized support |

OEM, ODM, OBM |

|

Gearing Arrangement |

Helical |

|

Output Torque |

3.5-56845N.m |

|

Input Speed |

0-3000rpm/min |

|

Output Speed |

0.1-356rpm/min |

|

Place of Origin |

China |

|

Product name |

K Series Parallel Shaft Helical Gear Reducer |

|

Output Torque |

10-62800N.m |

|

Output Speed |

750-3000rpm/min |

|

Input Speed |

0-3000rpm/min |

|

Input power |

0.12-250kw |

|

Mounting Position |

Foot Mounted. Flange Mounted |

|

Ratio |

3.77~281.71 |

|

Gearing Arrangement |

Helical |

|

Reduction ratio |

68 |

|

Hardness of Tooth Surface |

Tooth surface hardness |

Detailed Photos

Product Description

-K Series Helical Bevel Gearbox

K series product performance

High transmission efficiency, low energy consumption and superior performance. High rigidity cast iron box with ribs; hard-toothed gears are made of high-quality alloy steel, the surface is carburized and quenched and hardened, and the teeth are finely machined, with stable transmission, low noise, large bearing capacity, low temperature rise and long service life.

High hardness high grinding accuracy

The gears are made of high-quality alloy carburizing and quenching, the tooth surface hardness is as high as 60±2hrc, and the tooth surface grinding accuracy is as high as 5-6 grades.

Elaborate design

From the box to the internal gear, it adopts a complete modular structure design, which is suitable for largescale production and

flexible selection.

Save power

The standard reducer model is divided according to the form of decreasing torque. Compared with the traditional equal proportion division, it is more in line with customer requirements and avoids power waste.

Certifications

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

Precision and High-Accuracy Applications of Helical Gearboxes

Helical gearboxes are well-suited for precision and high-accuracy applications due to their unique design and performance characteristics:

- Helical Gearing: The helical gears in these gearboxes offer smooth and continuous meshing, resulting in reduced backlash and improved positioning accuracy.

- Efficiency: Helical gearboxes are known for their high efficiency, which minimizes energy losses and heat generation. This is crucial for maintaining precision in applications where even small deviations can have significant impacts.

- Noise and Vibration: The helical gear tooth engagement helps in reducing noise and vibration levels, making them suitable for environments where quiet operation is required.

- Load Distribution: Helical gears distribute load across multiple teeth, minimizing localized wear and extending the lifespan of the gearbox.

- Smooth Motion: Helical gearboxes provide smoother motion transitions, which is crucial in precision applications where jerky or sudden movements are undesirable.

- Positional Accuracy: The reduced backlash and improved meshing characteristics of helical gears contribute to higher positional accuracy, making these gearboxes ideal for applications such as CNC machines, robotics, and medical equipment.

- Compact Design: Helical gearboxes can achieve high gear ratios in a relatively compact form factor, making them suitable for applications where space is limited.

Examples of precision applications where helical gearboxes are commonly used include CNC machining, robotics, semiconductor manufacturing, medical equipment, and metrology devices. The combination of efficiency, smooth operation, and accuracy makes helical gearboxes a preferred choice for achieving consistent and reliable performance in such applications.

Troubleshooting Common Issues in Helical Gear Systems

Troubleshooting helical gear systems involves identifying and addressing common issues that can affect their performance. Here’s a step-by-step process:

- Visual Inspection: Begin by visually inspecting the gearbox for any signs of wear, damage, or misalignment. Look for worn or chipped gear teeth, oil leakage, and unusual noise.

- Noise Analysis: If noise is present, analyze its type and frequency. Whining or grinding noises could indicate misalignment or damaged gears, while clicking or knocking sounds might point to loose components.

- Lubrication Check: Ensure that the gearbox is properly lubricated with the recommended type and quantity of lubricant. Insufficient lubrication can lead to increased friction and wear.

- Alignment Check: Check the alignment of the gears and shafts. Misalignment can result in uneven wear, noise, and reduced efficiency. Realign components if necessary.

- Gear Inspection: Inspect gear teeth for signs of pitting, scoring, or wear. Replace any damaged gears to prevent further issues.

- Bearing Examination: Check the condition of bearings that support shafts and gears. Worn or damaged bearings can lead to increased vibration and noise.

- Tightening and Fastening: Ensure that all bolts, fasteners, and connections are properly tightened. Loose components can cause vibrations and noise.

- Load Analysis: Evaluate the load conditions and operating parameters of the gearbox. Ensure that the gearbox is not subjected to loads beyond its design capacity.

- Temperature Monitoring: Monitor the operating temperature of the gearbox. Excessive heat can indicate problems such as inadequate lubrication or overloading.

- Consulting Experts: If issues persist or if you’re unsure about the diagnosis and solution, consult gearbox experts or manufacturers for guidance.

By following this troubleshooting process, you can identify and resolve common issues in helical gear systems, ensuring optimal performance and longevity.

Helical Gear Meshing and Its Benefits

Helical gear meshing refers to the engagement of two helical gears with inclined teeth. The teeth are cut at an angle to the gear axis, creating a helix shape. When these gears mesh, the inclined teeth gradually come into contact, allowing for smoother and quieter operation compared to straight-toothed gears.

The benefits of helical gear meshing include:

- Reduced Noise: The gradual contact between helical gear teeth minimizes impact and noise during engagement, resulting in quieter operation. This is particularly advantageous in applications where noise reduction is essential, such as industrial machinery and automotive transmissions.

- Smooth Operation: Helical gears provide smoother and more continuous motion due to the gradual engagement of teeth. This feature makes them suitable for applications that require precise and controlled movement, such as CNC machines and conveyor systems.

- Higher Load Capacity: The helical tooth geometry allows for greater tooth contact area, distributing the load over a larger surface. This results in higher load-carrying capacity and improved durability, making helical gears suitable for heavy-duty applications.

- Efficient Power Transmission: Helical gears transmit power more efficiently due to their smooth engagement and increased contact area. This efficiency contributes to reduced energy consumption and heat generation in gearboxes.

- Less Vibrations: The gradual meshing of helical gears reduces vibrations, resulting in smoother operation and reduced wear and tear on gear teeth and bearings. This is especially important for extending the lifespan of the gearbox.

Overall, helical gear meshing offers numerous benefits, including reduced noise, smoother operation, higher load capacity, efficient power transmission, and reduced vibrations. These advantages make helical gears a popular choice in various industrial applications where performance, durability, and reliability are crucial.

editor by CX 2023-09-22