Product Description

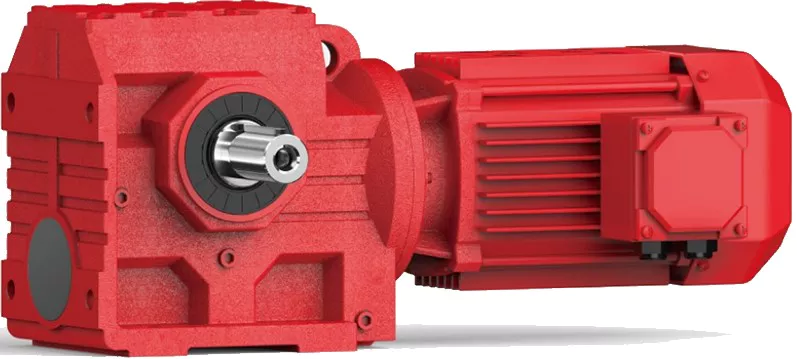

Reducer Spiral Bevel Helical Speed Reduction Agriculture Agricultural Cycloidal Servo High Precision Planetary Winch Track Wheel Slewing Drive Nmrv Worm Gearbox

Our products

Worm gearbox: RV series, WP series, SWL series screw jack, VF series

Helical gearbox: R/F/K/S series, HB series, BKM series, RC series, SMR shaft mounted gearbox, TA shaft mounted gearbox

Cycloidal gearboxes: BL/XL flange vertical installed double shaft type, BW/XW baseboard horizontal installed double shaft type, BLD/XLD flange vertical installed motor direct-connection type, BWD/XWD baseboard horizontal installed motor direct-connection type

Planetary gearbox: High precision planetary gearboxes, Planetary gearbox for feed mixer, Planetary gearbox for construction mixer, Travel drives, Winch drives, Slew drives, Inline gear reducer

Agricultural gearbox: Planetary gearbox for feed mixer, Flail Mower Gearbox, Rotary Tiller Gearbox, Lawn Mower Gearbox, rotary cutter gearbox, post hole gearbox, rotary mower gearbox, irrigation gearbox, fertilizer spreader gearbox, hydraulic drive gearbox, rotary rakes gearbox, hay tedders gearbox, sewage agitators gearbox, cutter bars gearbox, snowblower gearbox…

Our Advantages

–Box processing accuracy assurance

Large horizontal box machining center

High-end fully automatic multi-axis CNC boring and milling machine

Fully CNC high-precision processing ensures the accuracy of hole location

–Fourth level precision of precision gear grinding

The tooth surface is carburized and hardened, which is durable

Fine rolling and grinding process, high efficiency, stable and low noise

–Automatic numerical control workshop

Standardized CNC production workshop

Pass the ISO9001 quality system certification

Efficient operation to ensure production duration

–Diversified configuration and matching as required

It can be equipped with common three-phase/single-phase, braking, frequency conversion, explosion-proof, servo, and other motors.

Different motor voltage/frequency, protection grade, and energy efficiency grade can be configured.

Customizable input end cover matching non-standard power input device

–Automatic painting assembly line

Fully automatic painting assembly line

Ensure both internal and external products

Exquisite appearance and brand expression

–Rich customization design capability

Design technology team with more than 20 years of experience

Can undertake customization of various non-standard reducers

Company Profile

The company specializes in producing worm gearboxes (reducers), agricultural gearboxes, planetary gearboxes, helical gearboxes, swl series screw gearboxes, R, K, F, S series helical gear reducers, B/X series cycloidal pin gear reducers, etc. The products are exported to dozens of countries and regions in Europe, America, Japan, India, Brazil, etc. The products are mainly used in plastics, rubber, metallurgy and mining, petrochemical industry, hoisting and transportation, light industrial food, and other fields.

The company has exact and sensitive equipment, challenging tooth surface processing, and manufacturing equipment: German and Swiss gear grinders, gear testers, hobbing machines, large boring and milling machines, Japanese machining centers, etc.

More than 20 projects, such as the high torque reducer developed by the company, have won the national patent invention certificate and also won the national “high-tech enterprise certificate” in 2571.

Since its establishment in 2003, the company has adhered to the concept of “sustainable operation,” the business philosophy of “people-oriented, customer first,” and the core values of “unity, friendship, dedication, innovation, and efficiency.” The company keeps up with the cutting-edge technology in the market and strives to create the most satisfactory products for customers!

Product processing flow

Box processing process

Mechanical modeling of metal mold → casting on production line → artificial aging treatment → shot peening treatment → machining center processing → CMM detection

Gear processing process

Forging → normalizing → rough turning → fine turning → gear hobbing → chamfering of tooth end → carburizing and quenching (HRC58-62) → shot blasting → grinding of the end face and inner hole → gear grinding → accuracy testing (tooth shape, tooth orientation, tooth pitch, etc., level 6) → wire cutting keyway → magnetic particle flaw detection → ultrasonic cleaning and rust prevention.

Process flow of gear shaft processing

Forging → normalizing → rough turning (including center hole drilling) → finish turning → gear hobbing → keyway milling → carburizing and quenching (HRC58-62) → shot blasting → grinding center hole → excircle grinding → gear grinding → testing (tooth shape, tooth pitch, etc., level 6) → magnetic particle inspection → ultrasonic cleaning and rust prevention.

Certifications

Packaging & Shipping

How to select reducer

To determine the model of a reducer, the following parameters need to be determined:

1. Determine the running speed of the machine, and calculate the reduction ratio of the reducer according to this speed (reduction ratio=input shaft speed/output shaft speed=motor speed/mechanical required speed);

2. Calculate the load torque, select the output of the reducer according to this torque (refer to the “Output Torque Table” provided by the reducer manufacturer), and determine the reducer model;

3. Determine the additional functions of the reducer, such as power off braking, power on braking, frequency conversion, shrink frame, housing material, etc. Some additional functions can only be provided by specific factories.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Layout: | Coaxial |

| Hardness: | Soft Tooth Surface |

| Step: | Stepless |

| Transport Package: | Wooden Box |

| Specification: | Customize |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Lubrication Requirements for Maintaining Helical Gearboxes

Lubrication is essential for the proper functioning and longevity of helical gearboxes. The lubrication requirements include:

- Viscosity: Selecting a lubricant with the appropriate viscosity is crucial. The viscosity should provide sufficient lubrication and ensure a protective film between gear teeth under varying operating conditions.

- Extreme Pressure (EP) Properties: Helical gears often experience high contact pressures. Lubricants with EP additives form a protective barrier that prevents metal-to-metal contact and reduces wear.

- Oil Additives: Anti-wear additives, antioxidants, and corrosion inhibitors enhance the lubricant’s performance and protect gears from wear and degradation.

- Frequent Inspections: Regularly inspect the lubricant’s condition to detect contamination, degradation, or depletion. Scheduled oil analysis can help monitor the health of the lubricant.

- Proper Lubricant Application: Ensure the gearbox is properly filled with the correct amount of lubricant. Follow manufacturer recommendations for lubricant type and quantity.

- Lubricant Change Intervals: Establish regular lubricant change intervals based on operating conditions. Extreme conditions or heavy loads may require more frequent changes.

Appropriate lubrication minimizes friction, wear, and heat generation, leading to improved efficiency, reduced maintenance, and extended gearbox life. It’s crucial to follow the manufacturer’s guidelines and consult with lubrication experts to select the right lubricant and maintenance practices for your specific helical gearbox application.

editor by CX 2023-08-14